Our Capabilities

Sakura Tech is uniquely equipped with the right tools, equipment and expertise to manage your end-to-end requirements, starting from Tool Design to Mass Production.

Stage 1

Tool Design

- 2D / 3D

- Mold Flow

- AutoCAD / Inventor

- Unigraphics

- Pro E

- Specialize Gear Software

- Solid Designer

Stage 2

Prototyping

- Soft Tool

- Sampling

- Test Bed

Stage 3

Tool & Die Fabrication

- Precision Tooling

- (AGMA 12 - Gears)

- High Cavities

- (Stack Mold)

- Interchangeable Inserts

- (High Productivity)

- 100 tools / month

Stage 4

Injection Moulding

- Fully Electric

- European Technology

- 200 machines

- (50-650 tons)

Stage 5

Secondary & Value Added Process

- Silk Screen

- Heat Sticking

- Tampo printing

- Sub / Full Assembling

- Sourcing Support

Final Stage

Mass Production

Our Solutions

Mold Design

Format Capability

- 2D Design

- 3D Design

Software

- Uni-Graphics

- Pro-Engineer

- One Space Designer

- Customized Gear Design

- Moldex 3D (Mold Flow)

Product Engineering Solution & Prototyping

Customized Gear Design Simulation Software

- Debug design issue even before Prototyping

- Predict Potential Issue

- Maximize Success

- Time to Market

R & D Support

- Product Design

- Mechanism Design

- Design Improvement

- Prototyping

- Full Service Right Through Mass Production

Design Innovations

- Complex Tooling and High Precision

- New Technology Adaptation

- Technology to Drive Cost

- Time To Market Emphasis

Mold Design

Format Capability

- 2D Design

- 3D Design

Software

- Uni-Graphics

- Pro-Engineer

- One Space Designer

- Customized Gear Design

- Moldex 3D (Mold Flow)

Product Engineering Solution & Prototyping

Customized Gear Design Simulation Software

- Debug design issue even before Prototyping

- Predict Potential Issue

- Maximize Success

- Time to Market

R & D Support

- Product Design

- Mechanism Design

- Design Improvement

- Prototyping

- Full Service Right Through Mass Production

Design Innovations

- Complex Tooling and High Precision

- New Technology Adaptation

- Technology to Drive Cost

- Time To Market Emphasis

Tool & Die Fabrication

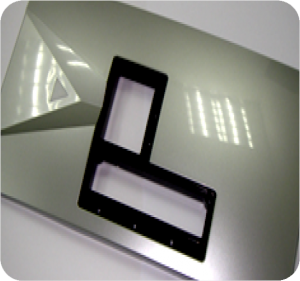

Housing/Skin

Engineering/Mech

Gear

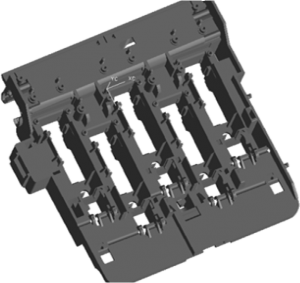

Connector

Interchangeable Insert Approach

- Technical Advantage

- Better Engineering Changes Flexibility

- Reduce Downtime when Supporting Globally

- Assurance of Supply with Spares

High Precision with Multiple Cavitations Capability

- Providing the Competitive Edge to Customers

- Pushing the Limit of Plastic Precision to Drive Cost

- Challenges the Complexity versus Manufacturability

Tool Techonology

- Stack Mold

- Cassette Mold

- Proto Mold

Tool & Die Fabrication

Housing/Skin

Engineering / Mechanic

Gear

Connector

Interchangeable Insert Approach

- Technical Advantage

- Better Engineering Changes Flexibility

- Reduce Downtime when Supporting Globally

- Assurance of Supply with Spares

High Precision with Multiple Cavitations Capability

- Providing the Competitive Edge to Customers

- Pushing the Limit of Plastic Precision to Drive Cost

- Challenges the Complexity versus Manufacturability

Tool Techonology

- Stack Mold

- Cassette Mold

- Proto Mold

Injection Molding

Independent Cavity Cooling System

- No Looping Allowed

- Accuracy Control

High Precision Machine

- Selectively - Sumitomo, Krauss Maffei, Engel & Sodick

- Sodick - Precision Plunger System & Camera System

Desiccant Drying System & Centralized Feed

- Technically essential for Engineering Plastic Resin

- Minimize Cross Contaminations risk.

Process Control System

- SPC

- Parameters Monitoring and Cavity Pressure ready

Mold Mainenance

- Daily Shot record due to various characteristic of Filled Resins

Aesthetic / Housing

Gear

High Precision

Insert Molding

Outsert Molding

Connectors

High Precision, Thin Wall

Various Types of Gears e.g. Typical Material POM, Nylon, Hytrel (PTFE, GF, SI, CF & Combination Filled)

Precision Molding ranging From PP, PS, ABS, HIPS, PC, PET, PBT, MPPO, PPS, PES, PSU, PEI, PEEK, COC. Full Range including CF, GF, Mineral, PTFE, SI, Bronze Filled & More

Injection Molding

Aesthetic/Housing

Gear

High Precision

Aesthetic/Housing

Gear

High Precision

High Precision

Various Types of Gears e.g. Typical Material POM, Nylon, Hytrel (PTFE, GF, SI, CF & Combination Filled)

Precision Molding ranging From PP, PS, ABS, HIPS, PC, PET, PBT, MPPO, PPS, PES, PSU, PEI, PEEK, COC. Full Range including CF, GF, Mineral, PTFE, SI, Bronze Filled & More

Our Equipment & Facilities

Tool Room

HIGH SPEED CNC MILLING

MOLD ASSEMBLY AREA

CNC MACHINE

EDM

WIRE-CUT

Dedicated Tool Testing Facility

Press Tonnage ranging

- 50 Ton

- 80 Ton

- 130 Ton

- 180 Ton

- 260 Ton

- 650 Ton

Metrology Enquipment

Smart Scope

CMM & Profile Projector

VEECO

DTM

Push/Pull Tester